One of one of the most considerable perks of magnetic belt conveyors is their potential to deal with iron components that are actually often hard to manage utilizing standard belt systems. In fields like reusing, scrap metal handling, and also production, metallic objects need to have to be actually moved securely without the danger of dropping or obtaining removed. The magnetic belt conveyor obtains this by embedding magnets either in the conveyor district on its own or under it, which generate a magnetic industry sturdy enough to hold onto metallic things. This attribute is specifically useful in reusing vegetations where metallic junk should be separated from other materials and transferred to assigned processing places. By utilizing the magnetic pressure to get materials in location, magnetic district bearers get rid of the requirement for hand-operated dealing with, making the whole procedure extra dependable and secure.

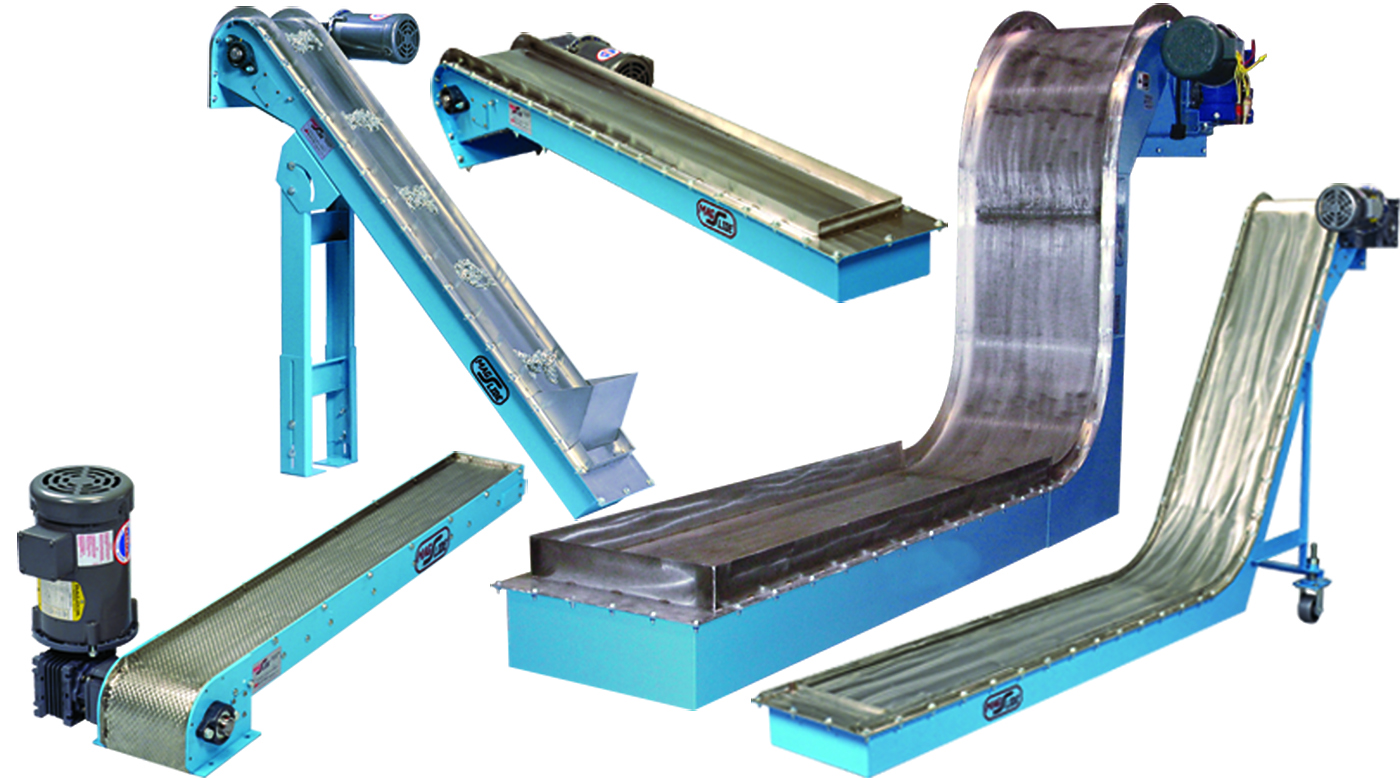

The layout of Magnetic Belt Conveyor enables all of them to be actually made use of in numerous industrial applications as well as environments. They are actually adjustable to different arrangements, including inclined, level, or even bent districts, relying on the particular needs of the function. These flexible designs enable the conveyors to move products horizontally, vertically, or at slants, guaranteeing that components are actually transferred properly across a production series or resource. Furthermore, magnetic bearers can be customized to deal with a variety of products, from small elements to large metallic sheets. The durability of the magnets can easily also be actually readjusted to satisfy the criteria of the product being actually handled, delivering a custom-made answer for industries along with differing demands. This adaptability produces Magnetic Belt Conveyor suitable for a large range of tasks, whether it's separating steel coming from various other products in reusing vegetations or sharing parts in producing vegetations.

The performance of Magnetic Belt Conveyor is one more element that specifies them other than standard bearers. The use of magnets permits for a continual circulation of materials, lowering the chance of disruptions in creation. Unlike various other bearers that might require regular changes or even servicing to deal with different products, magnetic bearers provide a much more stable as well as reputable ways of carrying iron things. The smoothness of the function indicates that there is less damage on the device, which minimizes the necessity for repair work and also expands the life of the tools. In fast creation atmospheres, this consistent, reputable motion of products is crucial for keeping productivity as well as lessening down time. The productivity of magnetic belt bearers aids make sure that procedures run effortlessly as well as that components are actually moved quickly and properly with the manufacturing process. To acquire new information please look at Tecnimetal

Among the standout components of magnetic district bearers is their reduced upkeep demands. Unlike standard conveyor units, which rely upon technical components like curlers and also garments that can easily experience wear eventually, magnetic bearers possess fewer moving components, which decreases the likelihood of mechanical breakdown. The lack of rubbing between the waistband and materials suggests that belts last longer as well as carry out certainly not need constant substitutes. In addition, considering that magnetic bearers are easier in style, they are actually less complicated to clean up as well as maintain, which is actually especially significant in sectors as if meals processing, where health criteria have to be actually stringently followed. The lengthy life-span as well as lessened upkeep demands create Magnetic Belt Conveyor a cost-effective remedy, as they help companies save money on both time as well as amount of money while maintaining smooth procedures.

The safety benefits of Magnetic Belt Conveyor also help in their common use. Handling heavy or even sharp metallic objects manually can position substantial threats to workers in various business, consisting of possible decreases, stress, or even other personal injuries. Through automating the transit of ferrous components, magnetic conveyors do away with the demand for straight interaction with unsafe components, lowering the threat of accidents. This automated component managing body likewise decreases the opportunities of items being actually misaligned or even falling off the bearer, which can easily lead to accidents or product damages. In sectors like recycling, where large quantities of junk metallic need to be actually dealt with, Magnetic Belt Conveyor not merely boost security yet likewise enhance total operational efficiency by minimizing the moment devoted personally arranging or taking care of materials. The assimilation of magnetic conveyors into automated systems further boosts workplace security.